Comparing carbon footprints

The common elements to measure for the carbon footprint calculation are defined by CEPI. They can help us to see the bigger picture.

Below, we have summarized them into four major headlines.

For each headline we'll go into details about how different factors affect carbon dioxide emissions.

Carbon storage

Paper is based on a renewable raw material, and the carbon footprint calculations start with the capacity of forests to bind CO2. Usage and recycling of paper and board products delays the bound carbon from returning to atmosphere, and depending on how the paper is used and reused, that time can be prolonged.

The first part of the carbon footprint calculation covers carbon stored in the product. This figure depends on whether the forest material can be converted to paper with a high yield, or if a lot of forest material goes to waste. For example in the chemical pulping process, the lignin which makes up almost 50% of the wood raw material is removed in the process and burned for heating. In a thermomechanical pulping process, 98% of the raw materials become paper pulp.

It's a good thing that paper binds carbon dioxide, as long as it is circulated and recycled with care, but to compare the emissions we need to focus on the other parts of the calculation.

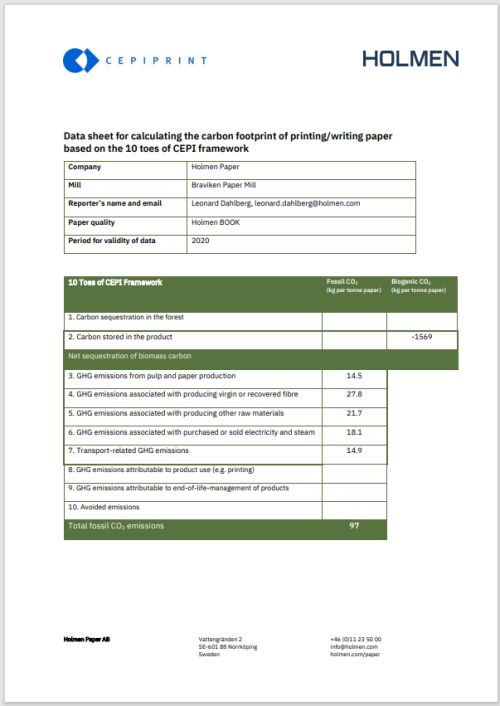

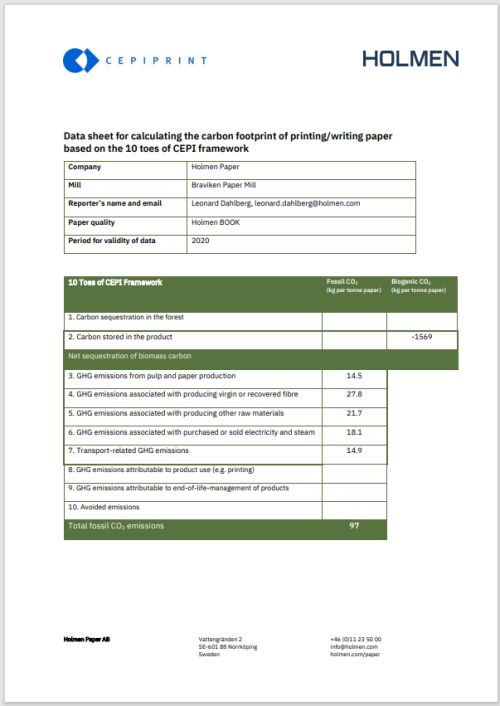

Click on the image to see a larger example of a carbon footprint calculation for a printing paper, in this case Holmen BOOK, produced at Holmen Braviken mill.

Emissions from manufacturing

The next steps in the carbon footprint calculation, step 3-6, count the emissions associated with the processes that transform the raw material into a final product. Here is where the emissions from electricity use are counted. These figures become lower when the paper is produced using energy from fossil free or renewable sources.

To produce 1 tonne of paper, how much carbon dioxide in kilos will be emitted in total? In the carbon footprint calculation example shown above, it's 97 kg, an emission rate of less than 1%.

To define the carbon footprint from your paper use, you need to first look at the total carbon dioxide emissions per tonne for your selected paper. Then decide which grammage you want to use and then finally, how much paper you will need.

Your printing contact can help you calculate how much paper you will need for your intended use, and then you can get a figure for the carbon dioxide emissions caused from the production of this paper.

Naturally this figure will be lower for a paper with a low amount of emissions per tonne, and even less if you can use a lower basis weight than your normal paper. To calculate how low you can go on basis weight and how much you can save in paper use, try our bulk calculator.

Emissions from transports

All transport induced carbon dioxide emissions until the paper leaves the mill, are included in the carbon footprint calculation for Holmen's papers. After that, the transports differ so much depending on the destination, they have to be calculated case by case.

Our carbon footprint example shows that emissions from internal transports are comparatively low, and this is thanks to synergies in Holmen's production. Holmen's paper mills get their raw materials from forest management in nearby forests, and wood chips from neighbouring sawmills. The mills also have their own deepwater ports to enable large scale shipping by sea. Carbon dioxide emissions from transports are monitored and an important part of the negotiations with all our transport suppliers. We encourage the use of transports by sea, rail and intermodal transports and many of our forwarders use fossil free HVO-fuel for truck transports.

The question of reducing impact from transportation is large and complex, so many factors need to be taken into the calculations. Our logistics department works thoroughly with balancing customer needs and efficiency with sustainability in mind.

Emissions from product use and end of life

When it comes to emissions from product use and emissions from end-of-life management (steps 8-9 in the carbon footprint), these can't be calculated by the paper supplier. Here, for example emissions related to printing are counted, which can be done further along in the production chain.

However, CEPI points out that user related emissions are very unusual for paper and board products, compared to for example electronic media, where electricity is needed for every view of a written message. This may be good to keep in mind when comparing the use of paper to other communication media.