Climate

Impacts, risks and opportunities

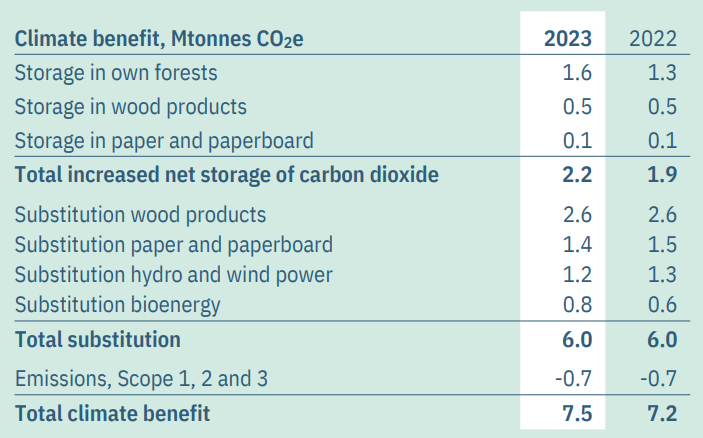

With nature as a starting point, climate issues are closely integrated with our activities. We strive to increase climate benefits in our value chain by both increasing our positive impact on the climate and reducing our negative footprint. Through sustainable forestry, where the trees are harvested when growth slows down and the land is reforested, we increase the forest's growth and carbon dioxide uptake over time.

The raw material continues to bind carbon dioxide even in refined form, such as long-lived wood products and short-lived board and paper products. The greatest climate benefit is achieved when our customers choose wood-based products and renewable energy instead of fossil-based alternatives.

The sale of renewable electricity from hydropower, wind power and biomass also helps to replace coal and gas power. In 2023, Holmen's operations generated climate benefits equivalent to 7.5 million tonnes of CO2e.

Physical transition risks and opportunities

A warmer climate can increase forest growth with longer growing periods and higher carbon dioxide levels, but also increase the risk of fungal infestation, insect damage and forest fires. We carry out continuous climate risk analyses and adaptation plans to ensure healthy forests.

Seedlings and forestry are adapted to a warmer climate, and seeds are selected to increase resistance to extreme weather. Climate change can also affect our industries and supply chain, which is managed through business continuity plans and ISO-certified systems. Increased demand for renewable products makes forestry crucial to our contribution to climate change mitigation.

Risk management

Energy use and energy mix

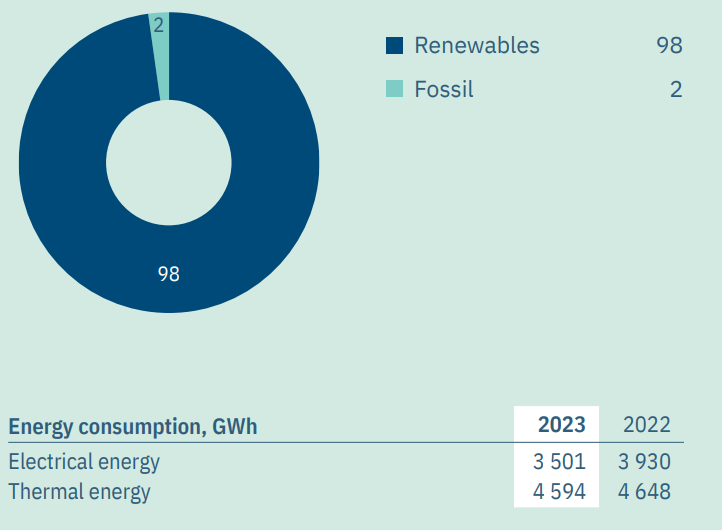

Holmen uses large amounts of energy and the absolute majority of the energy we use is fossil-free. In 2023, Holmen used a total of 8 (9) TWh , of which 7.9 (8.7) GWh was fossil-free, corresponding to 98 (97) per cent.

Biofuels, mainly in the form of bark and wood-containing lye, cover 96 (97) per cent of Holmen's need for thermal energy. The remaining amounts of heat are mainly produced at and adjacent to the mills with the help of natural gas, oil and LPG.

The production of thermomechanical pulp at our two paper mills requires electricity , and most of the electrical energy needed at Holmen's plants is purchased externally. The paperboard business produces the majority of the electricity needed at its own mills. In 2023, total electricity consumption amounted to 3.5 (3.9) TWh.

Energy use, %

Energy production

Holmen delivered 1.5 TWh of renewable electricity from hydro and wind power in 2023, which corresponds to 59% of our total electricity consumption. We produce 1,100 GWh of hydropower annually from 21 power plants and have two wind farms with a production of approximately 600 GWh.

In addition, we purchase 160 GWh annually from a wind farm on our land. In 2023, 2.7 TWh of biofuels were delivered from our sawmills and the forest. The surplus electricity and heat from our mills is sold externally, with 127 GWh of surplus electricity from Workington and 25 GWh of district heating from Iggesund Mill and Hallsta Paper Mill.