Cardboard

Cardboard is a widely used but rather undefined term, referring to paper pulp-based packaging materials, where the meaning can range from solid paperboard to different types of corrugated fibreboards.

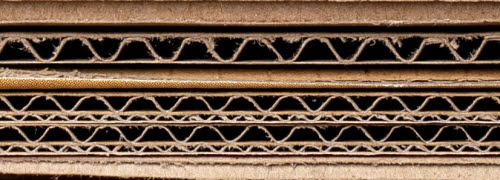

Corrugated cardboard

Corrugated cardboard means that at least one layer of the packaging material is corrugated, which reduces the weight of the board significantly, because this layer makes it possible to keep the stability and protection quality of the board even though less material is used. The corrugated layer is called fluting with reference to its hollow forms throughout the material. Since the material is made by fresh or recycled woodfibres, it can also be called corrugated fibreboard.

Paperboard

Paperboard is a solid paper-based packaging material. A premium paperboard is manufactured by another business area in our group: Holmen Iggesund.

Containerboard

Containerboard, or corrugated case material, CCM, are all the packaging component products manufactured for production of corrugated board; fluting medium papers, liner, and interliner paper, to be glued together in different layers depending on the desired end result. The word 'container' refers to the fact that the material construction contains air.

Wellenpapier, Wellenstoff, wellpapp, golfkarton etc

In German and some other languages, the corrugated material is referred to in the form of 'Wellen', meaning 'waves'. This can be noted also in Swedish, 'wellpapp', or as in Norwegian and Danish 'bölgepapp', wave-paper, or for example the Dutch 'golfkarton', from 'golven', which also means waves.